I-17.00-25 / 1.7 rim yeSixhobo soKwakha i-Wheel loader

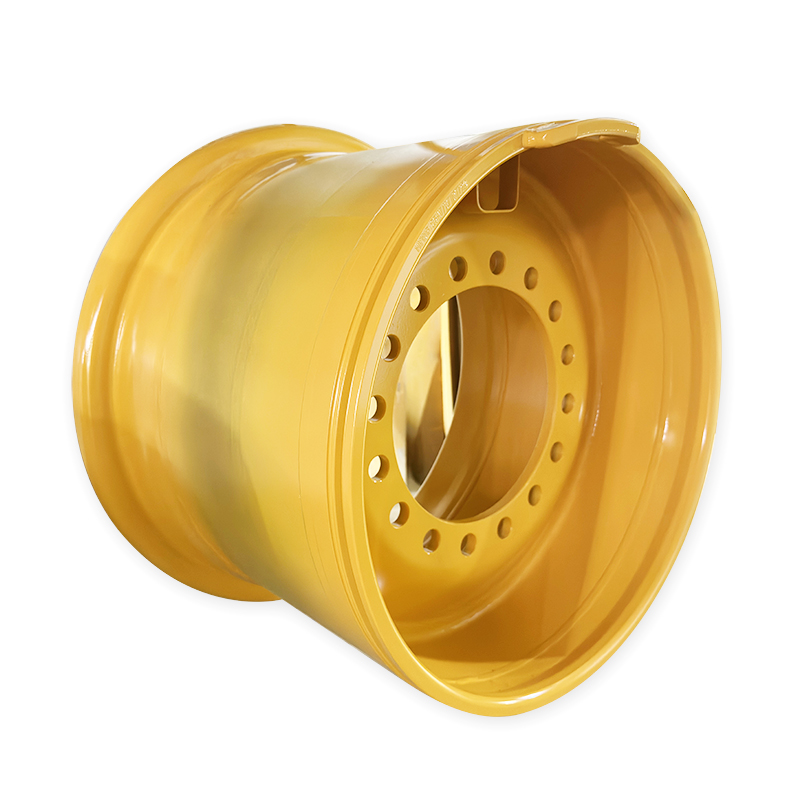

Amavili e-Original Equipment Manufacturer (OEM), akwaziwa ngokuba ngamavili esitokhwe, ngamavili afika ngokwesiqhelo kwizithuthi xa ziqala ukwenziwa. Inkqubo yokwenza amavili e-OEM ibandakanya amanyathelo aliqela, kubandakanywa ukuyila, ukukhetha izinto eziphathekayo, ukuphosa okanye ukuxova, umatshini, ukugqiba, kunye nolawulo lomgangatho.

Ii-Volvo Wheel Loaders zihlala zineempawu ezinje:

1. **Uyilo**: Amavili e-OEM aqala ngesigaba soyilo apho iinjineli kunye nabayili benza iinkcukacha zevili, kuquka imilinganiselo, isimbo, kunye nomthamo wokuthwala umthwalo. Uyilo lukwaqwalasela izinto ezinjengobunzima besithuthi, iimfuno zokusebenza, kunye nobuhle.

2. **Ukhetho lweMathiriyeli**: Ukhetho lwemathiriyeli lubalulekile kumandla evili, ukuqina, kunye nobunzima. Uninzi lwamavili e-OEM lwenziwa ukusuka nokuba yi-aluminium alloy okanye intsimbi. Amavili e-aluminium alloy axhaphake kakhulu ngenxa yobunzima bawo obulula kunye nobuhle obungcono. Ukuqulunqwa kwe-alloy ethile kukhethwe ngokusekelwe kwiipropati ezifunwayo zevili.

3. ** Ukuphoswa okanye ukuQinisa **: Kukho iindlela ezimbini eziphambili zokuvelisa ekudaleni amavili e-OEM: ukuphosa kunye nokukhwabanisa.

- **Ukujula**: Ekubumbeni, ingxubevange ye-aluminiyam etyhidiweyo igalelwa kumngundo onemilo yevili. Njengoko i-alloy iphola kwaye iqina, ithatha ubume bokubumba. Le ndlela iqhele ukusetyenziswa ekudaleni uyilo oluntsonkothileyo kwaye ineendleko eziphezulu zokuvelisa inani elikhulu lamavili.

- **Ukuqulunqa**: Ukuqulunqa kubandakanya ukubumba iibhilithi ze-aluminiyam ezifudunyeziweyo usebenzisa ucinezelo oluphezulu okanye iihamile. Le ndlela ikholisa ukuvelisa amavili anamandla nakhaphukhaphu xa kuthelekiswa nokuphosa, kodwa ibiza kakhulu kwaye ifaneleka ngcono izithuthi ezijolise ekusebenzeni.

4. **Machining**: Emva kokusasa okanye ukufoja, amavili ahamba kwinkqubo yomatshini ukucokisa imilo yawo, ukususa imathiriyeli engaphezulu, kunye nokudala iimpawu ezifana noyilo lwespoke, imingxuma ye-lug nut, kunye nomphezulu wokunyuka. Oomatshini abalawulwa ngekhompyutha baqinisekisa ukuchaneka kunye nokuhambelana kweli nqanaba.

5. **Ukugqiba**: Amavili angena kwiinkqubo ezahlukeneyo zokugqiba ukuphucula inkangeleko yawo kunye nokuwakhusela ekudlekeni. Oku kubandakanya ukupeyinta, ukugquma umgubo, okanye ukusebenzisa umaleko ocacileyo okhuselayo. Amanye amavili asenokupholishwa okanye enziwe ngoomatshini ukwenza ubume obukhethekileyo bomphezulu.

6. **Ulawulo loMgangatho**: Kuyo yonke le nkqubo yokwenziwa kwemveliso, kukho amanyathelo angqongqo okulawula umgangatho ukuze kuqinisekiswe ukuba amavili ayahlangabezana nokhuseleko, ukusebenza kunye nemigangatho yobuhle. Oku kubandakanya ukuvavanyelwa imfezeko yolwakhiwo, ibhalansi, imilinganiselo, kunye nokugqiba komphezulu.

7. **Uvavanyo**: Nje ukuba amavili enziwe kwaye agqityiwe, aphantsi kweemvavanyo ezahlukeneyo ezifana novavanyo lwe-radial kunye ne-lateral fatigue, uvavanyo lwempembelelo, kunye novavanyo loxinzelelo. Olu vavanyo lunceda ukuqinisekisa ukomelela kwamavili kunye nokuqina phantsi kweemeko ezahlukeneyo.

8. **Ukupakishwa kunye noSasazo**: Emva kokudlula ulawulo lomgangatho kunye novavanyo, iivili zipakishwa kwaye zisasazwe kwiiplanti zokudibanisa iimoto ukuze zifakwe kwizithuthi ezintsha. Zisenokufumaneka njengeendawo zokutshintsha ukuze zisetyenziswe emva kwentengiso.

Ngokubanzi, inkqubo yokwenza amavili e-OEM yindibaniselwano yobunjineli, isayensi yezinto eziphathekayo, ukuchaneka komatshini, kunye nolawulo lomgangatho ukuqinisekisa ukuba amavili ahlangabezana nokhuseleko, ukusebenza, kunye nemigangatho yobuhle ngelixa kuhambelana noyilo kunye nokusebenza kwesithuthi.

Ukhetho oluninzi

| Isilayishi samavili | 14.00-25 |

| Isilayishi samavili | 17.00-25 |

| Isilayishi samavili | 19.50-25 |

| Isilayishi samavili | 22.00-25 |

| Isilayishi samavili | 24.00-25 |

| Isilayishi samavili | 25.00-25 |

| Isilayishi samavili | 24.00-29 |

| Isilayishi samavili | 25.00-29 |

| Isilayishi samavili | 27.00-29 |

| Isilayishi samavili | DW25x28 |