Iirimu ezihlala zihlala zixhomekeke kwindawo kunye nezinto eziphathekayo zokusetyenziswa. Ezi ntlobo zerim zilandelayo zibonisa ukuqina okwahlukileyo kwiimeko ezahlukeneyo:

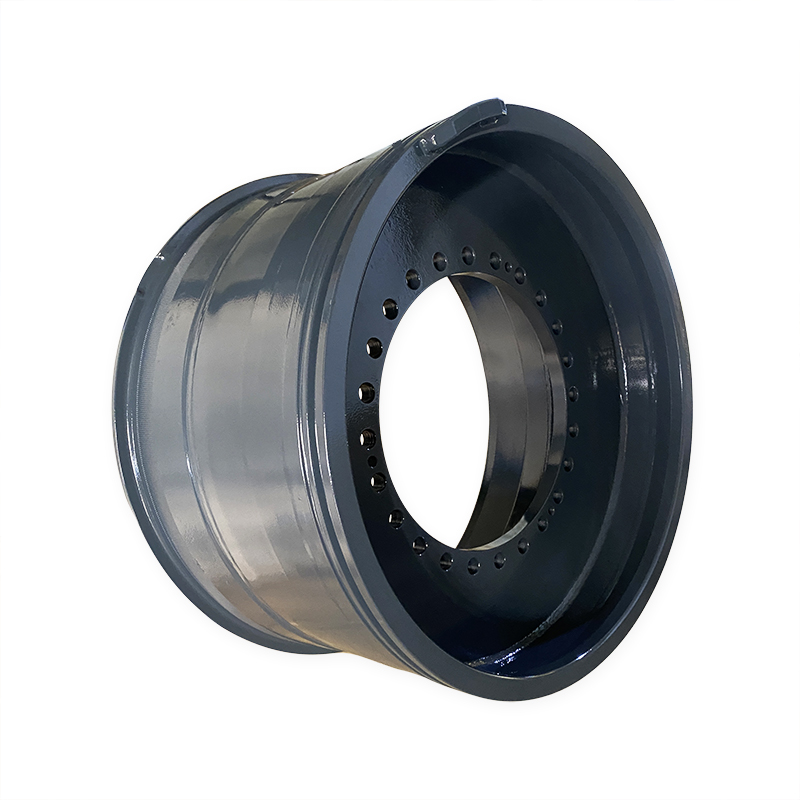

1. Iirim zentsimbi

Ukuqina: Iirimu zentsimbi yenye yezona ntlobo zizinzileyo zeerimu, ngakumbi xa ziphantsi kwempembelelo egqithisileyo okanye imithwalo enzima. Ziyakwazi ukumelana neempembelelo kwaye zinokumelana neempembelelo ngaphandle kokuqhekeka okanye ukwaphuka ngokulula.

Iimeko ezisebenzayo: Ilungele iimeko ezingqongileyo ezirhabaxa, izithuthi ezingekho ndleleni, iilori ezinzima, kunye noomatshini bokwakha. Ngokukodwa ezifanelekileyo kwiindawo ezineemeko ezinzima ezifana nemigodi kunye neendawo zokwakha.

Ukulungiswa: Ukuba iirimu zetsimbi zigobile, ngokuqhelekileyo ziyakwazi ukulungiswa ngezixhobo ezilula zokulungisa ngaphandle kokutshintshwa.

Isishwankathelo: Iirimu zetsimbi zezona zikhethwa kakhulu, zilungele imithwalo enzima kunye neemeko zendlela ezinzima ngenxa yamandla abo aphezulu kunye nokuqina.

2. Iirimu zealluminiyam ezenziweyo

Ukuqina: Iirim zealluminiyam ezenziweyo zinamandla aphezulu kunye nokuqina kuneerimu zealluminiyam eziqhelekileyo. Inkqubo yokubumba ibenza baxinene, baxhathise ngakumbi, kwaye babe khaphukhaphu.

Iimeko ezisebenzayo: Ifanelekile kwizithuthi ezisebenza kakhulu, iiSUV, kunye nezicelo ezifuna ukukhanya. Baqhuba kakuhle ekuqhubeni ezidolophini nakwiimeko zohola wendlela.

Ukulungiswa: Nje ukuba umphetho we-aluminiyam owenziweyo wonakele, kunzima ukuwulungisa kwaye ngokuqhelekileyo kufuneka utshintshwe.

Isishwankathelo: Iirimu zealluminiyam ezakhiweyo zifikelela kwibhalansi elungileyo phakathi kwamandla kunye nokukhaphukhaphu kwaye zinokomelela ngakumbi iirimu zealuminiyam.

3. Magnesium alloy rims

Ukomelela: Iirim ze-Magnesium alloy zikhaphukhaphu kakhulu, kodwa azomelelanga kwaye azinyangeki njengentsimbi okanye iirim zealluminiyam ezakhiweyo. Zifanelekile kwizihlandlo apho kulandelwa ukusebenza kunokuqina.

Iimeko ezisebenzayo: Ikakhulu isetyenziselwa ukubaleka kunye neemoto zemidlalo ezikumgangatho ophezulu, ezingafanelekanga ukuqhuba imihla ngemihla okanye iindawo ezinzima.

Ukulungiswa: Iirim ze-Magnesium alloy ziethe-ethe, kwaye xa zonakele, ukulungiswa kuba nzima kwaye kudla ngokufuna ukutshintshwa.

Isishwankathelo: Nangona ukukhanya, iirimu ze-magnesium alloy azihlali njengentsimbi okanye i-aluminium eyenziweyo, kwaye ifanelekile kwimidyarho okanye iminyhadala eneemfuno eziphezulu zokukhanya.

4. Iirimu zeCarbon fiber

Ukuqina: Iirimu ze-Carbon fiber zilula kakhulu, kodwa zinobunzima obunzima kwaye zonakaliswa lula yimpembelelo, efanelekileyo kwizicelo ezifuna ukukhanya okugqithisileyo kunye nokusebenza okuphezulu.

Iimeko ezisebenzayo: Umdyarho ophezulu okanye iimoto zezemidlalo ezisebenza kakhulu, ezidla ngokusetyenziswa kumzila.

Ukulungiswa: Xa zonakele, iirim zekhabhoni zefiber ziphantse zingenzeki ukulungiswa kwaye zidla ngokufuna ukutshintshwa ngokupheleleyo.

Isishwankathelo: Iirim zekhabhoni zefiber zigqwesa kubunzima obugqithisileyo, kodwa azifanelekanga kwindawo ezifuna ukuqina okuphezulu.

Ngoko ke, iirimu zetsimbi zezona zizinzileyo kwaye zifaneleke ngokukodwa kwiindawo zokusebenza ezinzima (ezifana nemigodi, iindawo zokwakha, njl.) Ezifuna ukuchasana kwempembelelo ephezulu kunye nomthamo womthwalo.

Iirimu zealluminiyam ezakhiweyo zomelele ngakumbi kwaye zinentsebenzo ephezulu. Banokulinganisela okuhle phakathi kokuqina kunye nokukhanya okulula kwaye bafanelekile kwizithuthi eziphezulu zokusebenza kunye nokuqhuba imihla ngemihla.

Ukuba ukuqina kuyona ingqwalasela ephambili, ngakumbi kwiindawo ezilukhuni, iirimu zensimbi zilona khetho lungcono. Ukuba zombini ukusebenza kunye nokuqina kuyafuneka, iirim zealluminiyam ezibunjiweyo zezona zilungileyo.

Ukukhetha iirimu ezifanelekileyo akunakukwandisa kuphela ukusebenza kakuhle kwesithuthi, kodwa nokwandisa ubomi benkonzo yamavili kunye nezixhobo. Umzekelo,i-17.00-35/3.5 ubukhulu berim ezisetyenziswa ziilori ezinkulu eziqinileyo zokulahla izithuthi zemigodi

Itekhnoloji yethu ikhule kakhulu ekuveliseni iirimu zelori yokulahla inkunkuma. Ezi zilandelayo zezinye zeesayizi esinokuzivelisa.

| Ilori yokulahla i-Rigid | 15.00-35 | Ilori yokulahla i-Rigid | 29.00-57 |

| Ilori yokulahla i-Rigid | 17.00-35 | Ilori yokulahla i-Rigid | 32.00-57 |

| Ilori yokulahla i-Rigid | 19.50-49 | Ilori yokulahla i-Rigid | 41.00-63 |

| Ilori yokulahla i-Rigid | 24.00-51 | Ilori yokulahla i-Rigid | 44.00-63 |

| Ilori yokulahla i-Rigid | 40.00-51 |

Kuba indawo yemigodi idla ngokuba ngumbhoxo kwaye ibandakanya umhlaba ontsonkothileyo onje ngemingxuma, amatye, udaka, amathambeka aphakamileyo, njl.njl., ukukhetha iirimu ezinobungakanani obukhulu obuchanekileyo obudityaniswe namatayara afanelekileyo kunokonyusa ukucocwa komhlaba kwesithuthi, kuphucule ukudlula kwesithuthi. , bancede bawele ngokukhawuleza imiqobo okanye umhlaba ongalinganiyo, kwaye uphucule uzinzo. Ukongeza, izithuthi zemigodi (ezifana neelori ezinkulu zemigodi kunye nezilayishi) zidla ngokufuna ukuthwala imithwalo enzima kakhulu, ngokufuthi iitoni okanye amakhulu eetoni zentsimbi ekrwada okanye imithwalo. Iireyimu ezinkulu zetsimbi zinokuxhotyiswa ngemithwalo emikhulu, zibonelela ngommandla omkhulu woqhagamshelwano kunye nomthamo wokuthwala, ngaloo ndlela ukusabalalisa ngokulinganayo imithwalo enzima kunye nokunciphisa umonakalo wetayara.

Indlela yokukhetha i-rim yensimbi efanelekileyo?

Ukukhetha i-rim yensimbi efanelekileyo kufuna ukuqwalaselwa ngokubanzi kohlobo lwesithuthi, ukusetyenziswa kwendawo kunye neemfuno ezithile. Oku kulandelayo zizinto ezininzi eziphambili zokukhetha kunye namanyathelo:

1. Qonda uhlobo nenjongo yesithuthi

Izithuthi ezahlukeneyo kunye neemeko zesicelo zineemfuno ezahlukeneyo zeerim. Izithuthi zemigodi, izixhobo zokwakha, iilori ezinzima kunye nezithuthi ezingekho endleleni zihlala zifuna iirim zetsimbi eziqinileyo nezizinzileyo, ngelixa iimoto zabahambi okanye izithuthi ezilula zinokuqwalasela ubunzima kunye nokubonakala kweerimu ngaphezulu.

Oomatshini abanzima kunye neenqwelo zemigodi: zifuna iirimu zentsimbi ezingqindilili, ezomeleleyo ezinokumelana nemithwalo ephezulu kunye neemeko zokusebenza ezigqithisileyo.

Iilori eziqhelekileyo okanye izithuthi ezingekho endleleni: Unokufuna i-rim ebetha ibhalansi phakathi kwamandla kunye nobunzima.

2. Khetha ubungakanani obufanelekileyo ngokweenkcukacha zetayara

Ubungakanani bomphetho: Qinisekisa ukuba ubungakanani (ububanzi nobubanzi) berim buhambelana netayara. Idiameter efanelekileyo yerim idla ngokuphawulwa ecaleni kwetayara, elifana ne "17", ebonisa ukuba kufuneka i-intshi ye-17-intshi. Ububanzi betayara kunye nomphetho kufuneka zihambelane ukuqinisekisa ukhuseleko lokuqhuba kunye nokusebenza.

Ukukhetha ububanzi: Ububanzi bomphetho kufuneka bube buncinci kancinci kunobubanzi betayara ukuqinisekisa ukuba itayara linokuhlanganiswa ngokuqinileyo kwirim ngelixa ligcina uxinzelelo lomoya olufanelekileyo kunye nokuzinza.

3. Jonga umthamo womthwalo werim

Ukulinganiswa komthwalo: Umthamo womthwalo weerimu zensimbi ubaluleke kakhulu, ngakumbi kwizithuthi ezinzima. Xa ukhetha, qiniseka ukuba umthamo womthwalo we-rim unokumelana nobunzima obupheleleyo besithuthi kunye nobunzima bayo obukhulu xa ulayishwe ngokupheleleyo. Umthamo womthwalo werim unokufumaneka ngokuqhelekileyo kwiinkcukacha zomenzi.

Iimfuno zomthwalo: Ukuba isithuthi sidinga ukuthutha rhoqo izinto ezinzima okanye ukuhamba kwiindawo ezinqabileyo, kuyimfuneko ukukhetha iirimu zetsimbi ezinemilinganiselo ephezulu yomthwalo ukuphepha ukugqoka okanye ukonakala kwangaphambili.

4. Qwalasela ungqameko lomphetho

I-Offset (ixabiso le-ET): I-Offset ibhekiselele kumgama phakathi komphezulu wokunyuswa komphetho kunye nomgca osembindini werim. I-offset echanekileyo iqinisekisa ukuba ivili lisebenza kakuhle kunye nenkqubo yokumiswa kwesithuthi. I-positive offset eninzi kakhulu inokubangela ukuba itayara lishwabene ngaphakathi, lichaphazele isiqhubeli kunye nokunqunyanyiswa, ngelixa i-negative offset eninzi inokubangela ukuba itayara liphume kakhulu, linyuse umthwalo kumacandelo okunqunyanyiswa.

Iimfuno zokucaciswa kwesithuthi: Khetha ungqameko oluchanekileyo ngokwemilinganiselo ecetyiswayo yokunciphisa isithuthi esibonelelwe ngumenzi wesithuthi ukunqanda ukuphatha okanye iingxaki zokuguga kwamatayara.

5. Ukumelana nokubola kunye nonyango lokwaleka

Iirimu zentsimbi zivame ukugqwala xa zibekwe kwindawo yangaphandle ixesha elide, ngoko ke kubalulekile ukukhetha iirimu ezineengubo ezintle zokulwa nokubola. Izithuthi zoomatshini bemigodi kunye nezokwakha zifuna umgangatho ophezulu wokukhusela umhlwa.

Ukukhethwa kwengubo: I-galvanizing, i-powder powder okanye enye i-anti-rust i-rust inokuphucula kakhulu ukuxhatshazwa kwe-corrosion ye-rim, ngokukodwa kwiindawo ezimanzi, ezinodaka kunye nezinothuli.

6. Nika ingqalelo kwinkqubo yokuvelisa kunye nomgangatho weerimu

Inkqubo yokuvelisa: Khetha iirim zentsimbi ezenziwe nge-welding ekumgangatho ophezulu kunye neenkqubo zokwenza ukuqinisekisa amandla azo okwakhiwa kunye nokuqina. Iirim ezinomsebenzi wobugcisa obuthathaka zinokuba neengxaki ezifana ne-welding exekethileyo kunye neziphene zezinto eziphathekayo, ezinokukhokelela ngokulula kumonakalo werim.

Ukuqinisekiswa kunye nemigangatho: Qinisekisa ukuba iirim zihlangabezana nemigangatho efanelekileyo yomgangatho kunye neziqinisekiso (ezifana ne-ISO, i-JIS okanye i-SAE), enokuqinisekisa ukhuseleko kunye nokuthembeka kweerimu ngexesha loyilo kunye nenkqubo yokuvelisa.

7 Qwalasela ubunzima beefeleni

Nangona iirim zentsimbi zinobunzima kuneerimu zealuminiyam, iirim zentsimbi ezahlukeneyo zinokwahluka ngokobunzima. Kwizithuthi ezifuna ukuhamba rhoqo, iirim zentsimbi ezikhaphukhaphu zinokunciphisa ubunzima besithuthi, ziphucule ukusebenza kakuhle kwamafutha, nokuphucula ukuphatha.

8. Nika ingqalelo ukuhambelana kwezixhobo

Ipatheni yebholithi yehabhu: Qinisekisa ukuba inani kunye nolungiselelo lwemingxuma yebholiti kumphetho ihambelana ne hub yesithuthi. Ipateni yebholiti (efana no-4×100, 5×114.3) kufuneka ihambelane neerimu zesithuthi sokuqala ukuqinisekisa ukufakwa ngokukhuselekileyo.

Ubungakanani bomngxuma osembindini: Umngxuma osembindini werim yentsimbi kufuneka ungqamane ngokuchanekileyo nehabhu yevili lesithuthi ukunqanda ukonakala kwerim okanye iingozi zokhuseleko ngenxa yokukhululeka.

9. Uhlahlo lwabiwo-mali kunye neendleko zokugcina

Iirimu zentsimbi zitshiphu ngokubanzi kuneerimu ezenziwe ngezinye izinto, kodwa ixabiso liyakwahluka ngokuxhomekeke kumgangatho kunye nonyango lokuchasa umhlwa. Khetha umgangatho ophezulu, iirimu zetsimbi eziqinileyo, nangona iindleko zokuqala zinokuthi ziphakame kancinci, kodwa iindleko zokugcinwa ziya kuba ziphantsi ekusebenziseni ixesha elide.

Xa ukhetha i-rim yentsimbi echanekileyo, okokuqala qinisekisa ukuba ubungakanani bomphetho, umthamo womthwalo kunye ne-offset ihlangabezana neemfuno zesithuthi, kwaye ube nokhuseleko oluhle lokutya kunye nenkqubo yokuvelisa. Ukuba isithuthi sisetyenziselwa imisebenzi enzima okanye imimandla enzima, ukuqina kunye nomthamo ophezulu wokuthwala umthwalo zizinto eziphambili; kwizithuthi eziqhelekileyo ezingekho endleleni okanye iilori, ibhalansi phakathi kwamandla kunye nobunzima iyafuneka.

Siyinombolo yokuqala yaseTshayina yomyili wevili kunye nomvelisi, kunye nengcali ekhokelayo yehlabathi kuyilo lwecandelo kunye nemveliso. Zonke iimveliso ziyilelwe kwaye ziveliswa ngokwemigangatho ephezulu yomgangatho, kwaye sineminyaka engaphezu kwama-20 yamava kwimveliso yamavili. Sibandakanyeka ngokubanzi koomatshini bobunjineli, iirim zemoto yemigodi, iirim zeforklift, iirim zefektri, iirim zezolimo kunye nezinye izincedisi zerim kunye namatayara. Singumthengisi werim wokuqala eTshayina kwiimveliso ezaziwayo ezifana neVolvo, Caterpillar, Liebherr, kunye noJohn Deere.

Sineqela lophando kunye nophuhliso eliqulunqwe ziinjineli eziphezulu kunye neengcali zobugcisa, zijolise kuphando kunye nokusetyenziswa kobuchwepheshe obutsha, kunye nokugcina indawo ehamba phambili kwishishini. Siye saseka inkqubo epheleleyo yenkonzo emva kokuthengisa, ukubonelela ngenkxaso yobugcisa ngexesha nangempumelelo kunye nokugcinwa kokuthengisa emva kokuthengisa ukuqinisekisa ukuba abathengi banamava agudileyo ngexesha lokusetyenziswa. Ukuba unayo nayiphi na ingxaki kunye nemibuzo ekufuneka udityanwe nayo, ungaqhagamshelana nathi!

Oku kulandelayo bubukhulu obahlukeneyo beerimu ezinokuveliswa yinkampani yethu kwiinkalo ezahlukeneyo:

Ubungakanani oomatshini bobunjineli: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 10.00-25, 11.25-25, 12.00-25, 20-10-10, 20-10, 20-13, 20-13. 25, 19.50-25, 22.00-25, 24.00-25, 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 13.00-33

Ubungakanani bemigodi: 22.00-25, 24.00-25 , 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 28.00-33, 16.00-305-305-305-305, 30-30. 49 , 24.00-51, 40.00-51, 29.00-57, 32.00-57, 41.00-63, 44.00-63,

Ubungakanani beForklift zezi: 3.00-8, 4.33-8, 4.00-9, 6.00-9, 5.00-10, 6.50-10, 5.00-12, 8.00-12, 4.50-15, 5.50-15-00-10-15, 5. 15, 8.00-15, 9.75-15, 11.00-15, 11.25-25, 13.00-25, 13.00-33,

Industrial vehicle sizes are: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 7.00x12, 7.00x15, 14x25, 8.25x16.5, 9.75x16.5, 16x17, 13x15 .5, 9x15.3, 9x18, 11x18, 13x24, 14x24, DW14x24, DW15x24, DW16x26, DW25x26, W14x28, DW15x28, DW25x28

Ubungakanani koomatshini bezolimo: 5.00x16, 5.5x16, 6.00-16, 9x15.3, 8LBx15, 10LBx15, 13x15.5, 8.25x16.5, 9.75x16.5, 9x18, W.8x18, W , W7x20, W11x20, W10x24, W12x24, 15x24, 18x24, DW18Lx24, DW16x26, DW20x26, W10x28, 14x28, DW15x28, DW25x28, W11x16x30, W14x16x30, W11x30, W14x30, x42, DD18Lx42, DW23Bx42, W8x44, W13x46, 10x48, W12x48

Iimveliso zethu zikumgangatho wehlabathi.

Ixesha lokuposa: Oct-29-2024